Today was an amazing experience in my 3d printing journey.

We have this sink in our bathroom without a drain stopper. I tried to buy one but the sink is old and fickle and none ever worked. It has a narrow diameter and needed to be longer than any I could find……Challenge Accepted.

My goal today was to design and print a replacement….ready….GO!

BLUE PRINTING

Now, we have another similar sink that does have a stopper in place, so I removed it and started sketching up a blue print with measurements.

MODELING

I then loaded up Tinkercad and started forming my design. I’m still getting used to Tinkercad’s layout and tools as well as learning how to make them work in my favor. 😀

I split the model I to two pieces because I was a little hesitant on if I could build it so tall. It was fun figuring out a way to connect the two pieces together.

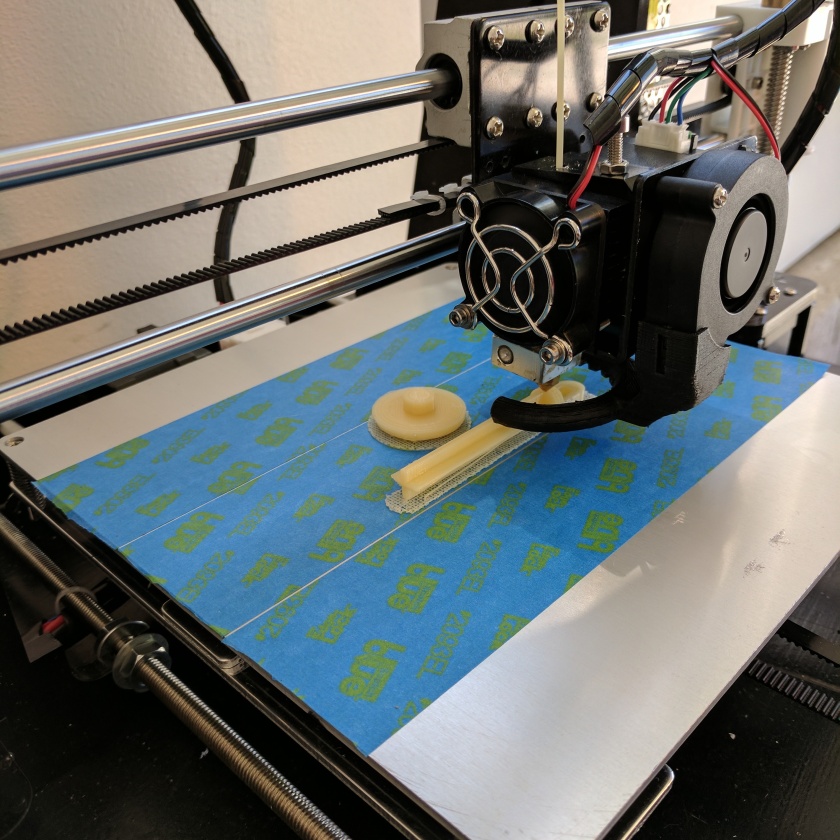

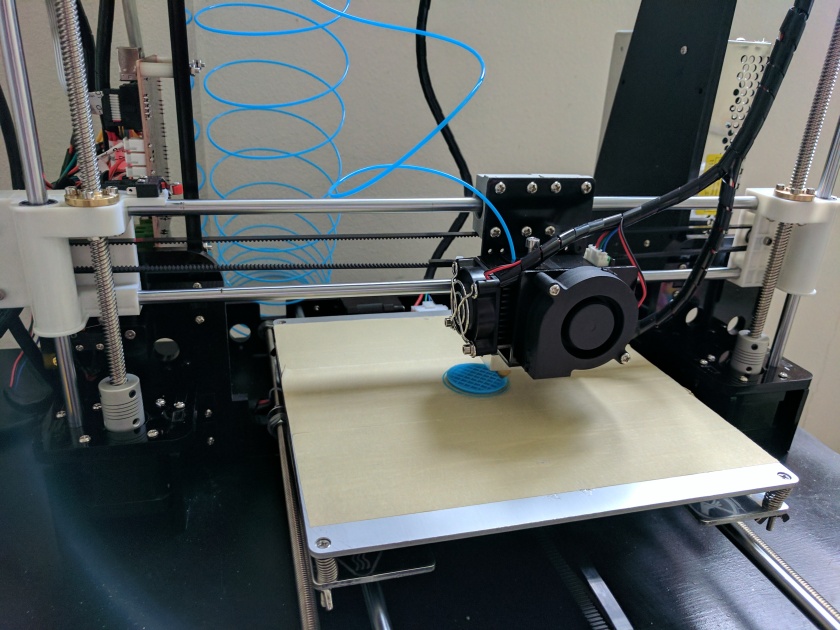

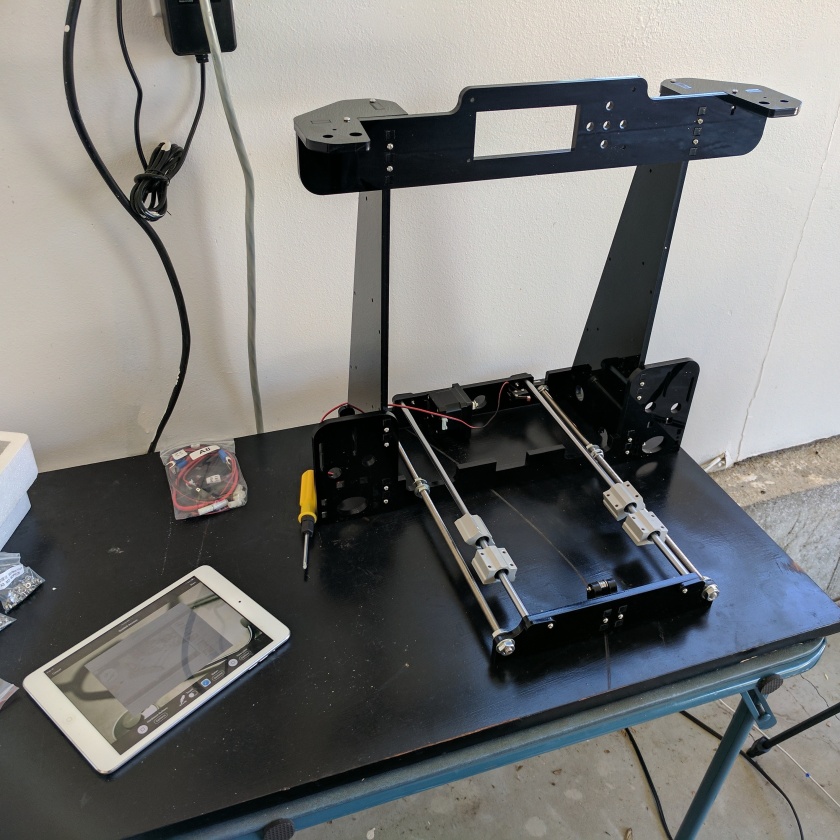

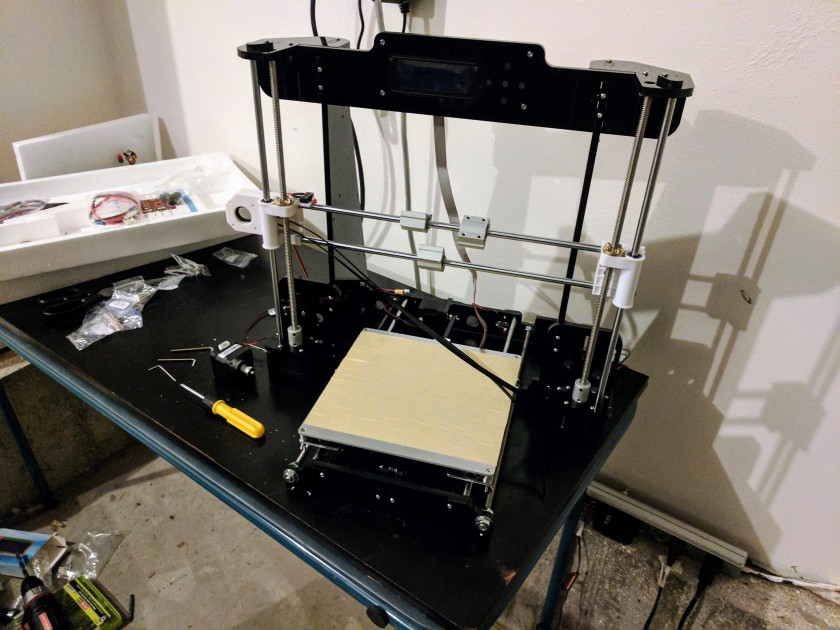

PRINTING

I tried a new setting for the first time. I printed the pieces on a raft to help with adhesion. And though a little problem with overhang, it printed!!!

I did attempt some post-print finishing with spray paint but in the end (after a few hours of going in circles) scraped it.

Finished Product!

What a beautiful sight; and…IT WORKS!!

What a beautiful sight; and…IT WORKS!!

This is just so amazing. To think something up and design what you need. To create right before your eyes. And even better is when it is a useful print that brings along a benefit in some way. I love the trinkety things I have and will still print, but this was such a satisfying undertaking and I am just amazing that such technology exists and is available right at our fingertips!

Great Day!